From Seed to Scoop, How Matcha is Made

Posted by Aiya Matcha on Jun 17th 2020

Matcha: A Japanese Green Tea

By now you’ve probably seen it everywhere, maybe at your local coffee shop or all over your Instagram feed. So what exactly is it? Matcha, in a nutshell, is a powdered green tea from Japan. Typically used in Japanese tea ceremonies and in various green tea flavored treats, it’s actually been around for over 800 years. More recently though, it’s gained traction here in the U.S. for its amazing health benefits and versatility as an ingredient. Now that you’re a bit more familiar, let’s talk about to how it’s made.

Like most other teas, Matcha is derived from the leaf of the Camellia Sinensis plant. With a few exceptions (such as rooibos and other herbal tea varieties), almost all other teas come from this same plant. However, what makes Matcha unique lies in the way it is cultivated and refined.

Cultivation: Hand Picked Care

Your standard teas (black, green, white, and oolong), are grown in the open with direct exposure to sunlight. Matcha, however, spends its last month before cultivation in the shade. To do this, the farmers first erect a skeleton-like framework above the plants.

Once the framework is set, layers of tarp are added to the top every week for a month until harvest. By the time the leaves are picked, about 90% of sunlight is blocked from reaching the plants.

This simple shade-growing process is actually one of the most important factors for growing Matcha—and we’ll explain why. Once the tarps are added, the plants begin to overproduce chlorophyll (which is what gives it its beautiful jade green hue) to continue the photosynthesis process in lack of light. This sunlight deficiency results in the preservation of amino acids within the leaf that are normally destroyed when exposed. In turn, these amino acids give Matcha its natural sweetness. Additionally, the surface of the leaves broaden, making them more delicate and tender, allowing them to be ground down into a fine powder. Ultimately, this simple process of blocking sunlight helps the plants transform into a completely different leaf.

When it comes time to harvest, the highest quality leaves are hand-picked, though lower grades may be machine picked to save time and cost. The placement of the hand and the angle at which the leaves are picked are very important during the harvest. To protect the delicate leaves from being prematurely torn or damaged, the leaves must be picked at a downward angle.

Once the picked leaves are collected, they are sifted through a vibrating belt to remove any unwanted materials. Then, they are lightly steamed to stop the natural decomposition of the leaf. Tea leaves in this state are called Aracha.

Refining: Only the Cream of the Crop

After the cultivation process, the lightly steamed tea leaves are further refined to separate the “meat” of the leaf from the veins, stems, and other undesired parts. This is achieved by a system of air blowers – the heavier stems fall first, while the lighter “meaty” parts fly further. Once separated, the lighter parts of the leaves are packed then sent off to be ground into Matcha. The other parts are used to make other Japanese teas, such as Kukicha or Konacha—no parts of the leaf are wasted. The leaves in this state are now called Tencha.

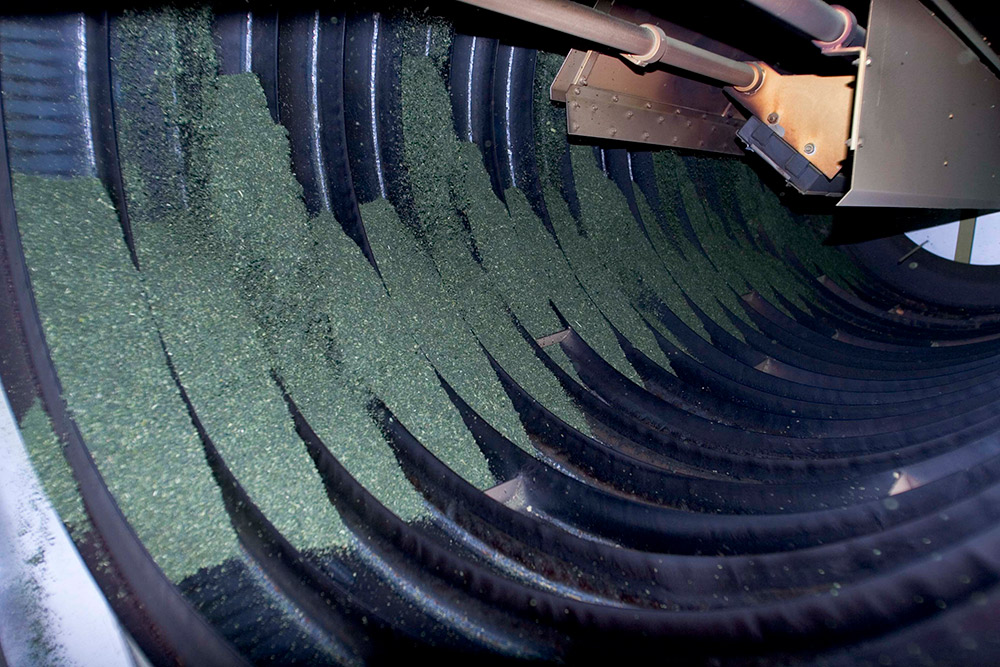

When the Tencha leaves arrive at the main plant, it is cold stored until an order is received. This allows for fresher, longer lasting batches of Matcha. To begin the process, the Tencha leaves are placed into granite grinders, a tool that has been used to make Matcha for over hundreds of years. (Fun fact: in modern day Japan, there are only about 10 artisans that have the skills and capabilities required to create, shape, and maintain these instruments!) The granite grinder then grinds the leaves down to a very fine powder by spinning and rubbing without producing excessive heat from friction. Although the grinder is reliable and extremely effective, it is not quick– it takes approximately one hour to fill a single 30 gram tin of Premium Matcha.

After the Matcha is ground, it is sifted one last time to ensure that there are no unwanted items in the batch. The sifted Matcha is carefully packed by hand into each individual tin for shipment and sale. As a result of the care, effort, and attention from seed to scoop, the Matcha is sent out to be enjoyed all over the world.

Welcome to Aiya's website! FREE standard shipping available for retail consumer orders over $50 & wholesale orders over $500 (U.S. and Canada).

Welcome to Aiya's website! FREE standard shipping available for retail consumer orders over $50 & wholesale orders over $500 (U.S. and Canada).